Bullet-resistant glass is comprised of multiple layers of float glass. All glass starts as float glass and is acquired in stock sheets.

The glass may be heat-strengthened or toughened by heating in a furnace. For bullet resistant glass this process does not need to occur. It is safer for the glass to be float when laminated as when impact strikes the glass will break into larger shards but the integrity holds, held together by the interlayer.

The glass may be heat-strengthened or toughened by heating in a furnace. For bullet resistant glass this process does not need to occur. It is safer for the glass to be float when laminated as when impact strikes the glass will break into larger shards but the integrity holds, held together by the interlayer.

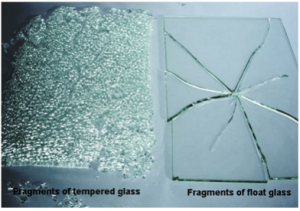

As you can see from the photo, toughened (tempered)glass breaks into hundreds of tiny fragments, if one bullet caused this pattern the integrity of the panel is compromised and a further attack could mean the panel failing completely. Bullet-resistant panels are made to bespoke sizes as per the customers request. The glass is cut by trained operatives using a cutting machine. When manufacturing a No Spall construction the polycarbonate is cut in a similar way.

As you can see from the photo, toughened (tempered)glass breaks into hundreds of tiny fragments, if one bullet caused this pattern the integrity of the panel is compromised and a further attack could mean the panel failing completely. Bullet-resistant panels are made to bespoke sizes as per the customers request. The glass is cut by trained operatives using a cutting machine. When manufacturing a No Spall construction the polycarbonate is cut in a similar way.

Once the glass is fully prepared it moves on to the next stage; preparing the interlayer that will enable the glass to ‘stick’ together. This process is carried out in a clean room environment to reduce the chance of fibres or foreign bodies appearing in the finished product. The interlayer is cut slightly bigger than the glass and layered on top of each piece of glass like a sandwich.

Once the glass is fully prepared it moves on to the next stage; preparing the interlayer that will enable the glass to ‘stick’ together. This process is carried out in a clean room environment to reduce the chance of fibres or foreign bodies appearing in the finished product. The interlayer is cut slightly bigger than the glass and layered on top of each piece of glass like a sandwich.

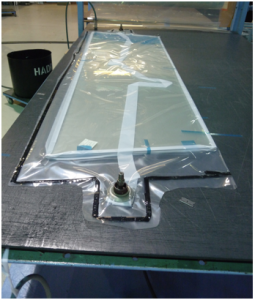

When finished the layered glass is placed in a ‘vac bag’.

When finished the layered glass is placed in a ‘vac bag’.

Vacuum bagging or ‘vac bagging’ removes trapped air, compacts the glass and interlayer, reduces humidity and prepares the raw materials for lamination.

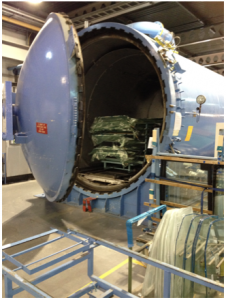

When ready the vac bag is loaded into the Autoclave and programmed accordingly. All glass constructions will go on a different ‘cycle’ compared to a glass polycarbonate construction. This is due to the different rates of expansion and contraction the materials have. An all glass construction will heat and cool at the same rate, however the polycarbonate layer in a No Spall construction expands and contracts at different rates to the glass it is being bonded to and therefore needs to be heated and cooled at a slower rate.

When ready the vac bag is loaded into the Autoclave and programmed accordingly. All glass constructions will go on a different ‘cycle’ compared to a glass polycarbonate construction. This is due to the different rates of expansion and contraction the materials have. An all glass construction will heat and cool at the same rate, however the polycarbonate layer in a No Spall construction expands and contracts at different rates to the glass it is being bonded to and therefore needs to be heated and cooled at a slower rate.

When the laminate has finished it is removed and left before being removed from the vac bag and the excess interlayer being trimmed away so the construction has a cleaner finish. This is done with hand tools by an experienced operative. The overhang may occur when the construction was compressed during lamination, pushing the interlayer out. When finished the glass is inspected to ensure it passes the quality tolerances for the product. For more information on glass tolerances please click here.

This is a brief outline of the process the glass undergoes to produce a bullet-resistant/ ballistic product.

This is a brief outline of the process the glass undergoes to produce a bullet-resistant/ ballistic product.

For more information on the standards Architectural Armour offer please view our Technical Specs and our Bullet Specs.

Please contact us with any questions or to discuss your project requirements.